NERAK's pendulum bucket conveyors are perfect for applications requiring multiple discharge points. Used to convey powder & bulk materials vertically or horizontally to one or multiple discharge points without the need for intermediate transfers, they deliver smooth and continuous travel throughout the system.

NERAK pendulum bucket conveyors are available in the typical "Z" and "C" conveyor configurations, but also in many other unique configurations. In "O" configuration, they can be used as a recirculation conveyor for packaging systems. All NERAK conveyors are designed to meet your project requirements.

Conveying capacities of up to 45 ft3/min (80 m3/hr) are possible.

Application Examples:

Pendulum bucket conveyors are available for handle a wide range of products, including:

Delicate foods

Chemicals

Pharmaceuticals

Sand

Gravel

Ores

Crushed rock

NERAK bucket conveyors offer gentle operation that minimizes spillage, product loss, mixture separation, or material breakup. Available in several bucket sizes to meet your material flow requirements, NERAK bucket conveyors have minimal space requirements.

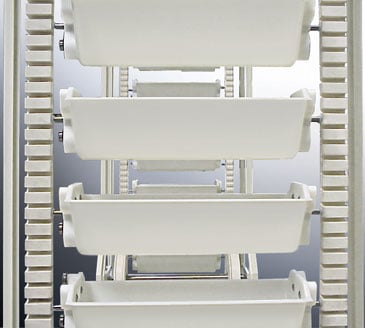

Single-mounted buckets are typically made of heavy injection-molded rigid fiberglass reinforced nylon, with thick, heavy walls. With large overlaps, they form a bucket string secured by strong rods to the Rubber Block Chains. The Rubber Block Chains do not stretch, ensuring guaranteed overlap for the product’s lifecycle.

Buckets can be made from materials including carbon steel, aluminum, stainless steel, and plastics like POM for high temperature applications and conductivity. The buckets stay in an upright position throughout the conveying run, and are only tilted during the discharge process.

Feed openings can be placed anywhere on the lower horizontal or incline area of the conveyors, and the length of the opening is designed to meet your specifications. All feed openings have a brush or flexible strip feed seals on all four sides to prevent spillage at the feed point.

Discharge openings can be placed anywhere on the upper horizontal sections of the bucket conveyor, even on the bottom horizontal sections, with tilt stations either fixed for permanent discharge or with on-off settings for controlled discharge. All pendulum bucket conveyor tilt devices are remotely controllable by means of either electromagnetic or pneumatic cam mechanisms.

Discharge assists such as thumpers and anti-static units are available for difficult to discharge or static-charged materials.

The casing of the standard bent sheet metal conveyor can be constructed for dust-tight and both vacuum- or pressure-tight operation, and include easy access clean-out, service and monitoring openings (with doors), as well as special design features on request.

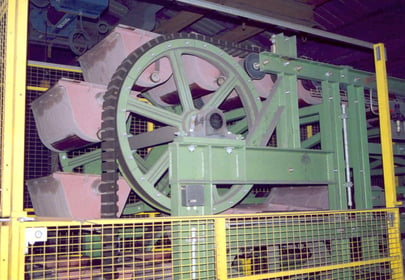

For special purposes, open frame construction conveyors made from square tubing with OSHA guarding as required are available. Internal parts are easily accessible via removable panels.

Conveyors for explosion hazard environment operation are designed using reinforced construction and, if required, can be equipped with protective devices such as explosion vents.

Carbon steel conveyors are wet-painted (using enamel or epoxy paints) or powder-coated to customers’ requirements. Casings made of either 304 or 316 stainless steel in any requested surface finish are constructed identically to the carbon steel construction and are part of our range of products.

Many options are available, including: